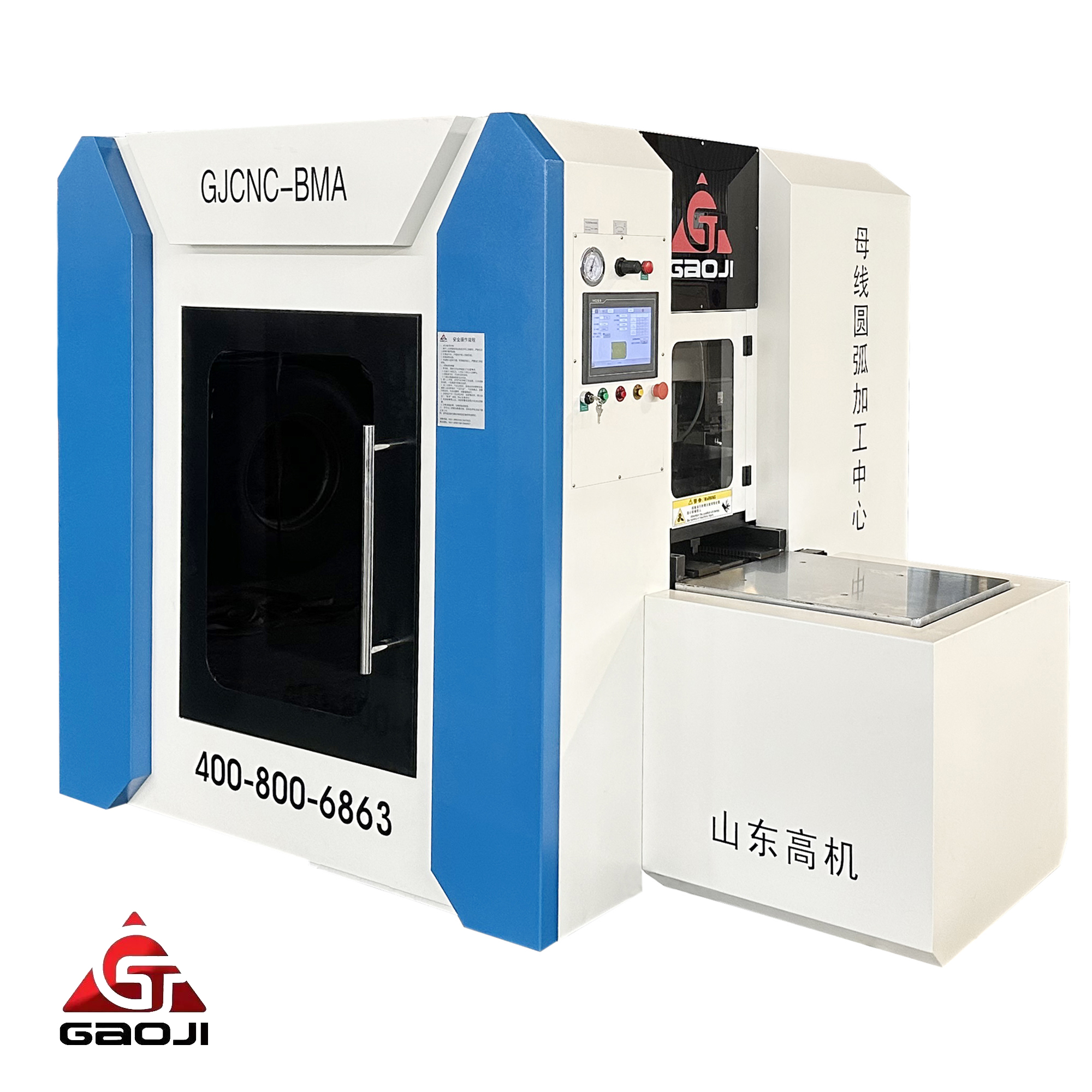

Mutengo wakaderera weCNC Automatic Copper High Effiency Busbar Processing Milling Machine Bus Arc Machining Center Chamfering Machine

Chinangwa chedu chinofanira kunge chiri chekusimbisa nekusimudzira mhando yepamusoro uye sevhisi yezvinhu zviripo, panguva imwe chete tichigadzira zvigadzirwa zvitsva nemhinduro kuti zvizadzise zvinodiwa nevatengi vedu. Mutengo wakaderera weCNC Automatic Copper High Effiency Busbar Processing Bending Punching Cutting Machine. Bus Arc Machining Center Chamfering Machine, Isu tiri vamwe vevagadziri vakuru ve100% muChina. Makambani makuru ekutengesa anotenga zvinhu kubva kwatiri, saka tichakupai mutengo unoshanda zvikuru une mhando yakafanana kana muchida.

Chinangwa chedu chinofanira kunge chiri chekusimbisa nekuvandudza mhando yepamusoro uye sevhisi yezvinhu zviripo, ukuwo tichigadzira zvigadzirwa zvitsva nemhinduro kuti zvizadzise zvinodiwa nevatengi vedu.Muchina weMabhazi eOtomatiki uye Muchina weMabhazi eCopperKana paine chimwe chezvinhu izvi chaunofarira, munofanira kutizivisa. Tichagutsikana kukupai mutengo kana mawana ruzivo rwakadzama rwenyu. Tine mainjiniya edu eR&D ane ruzivo rwekuzvibatsira kuti agadzirise chero zvinodiwa nemunhu. Tinotarisira kugamuchira mibvunzo yenyu munguva pfupi iri kutevera uye tinotarisira kuwana mukana wekushanda nemi mune ramangwana. Tinokugamuchirai kuti muone kambani yedu.

Ruzivo rweChigadzirwa

Muchina wekugaya weCNC busbar unoshanda zvakanyanya mumill fillet uye big fillet mubusbar. Unogadzira otomatiki kodhi yepurogiramu uye unotumira kodhi yacho kumidziyo zvichibva pane zvinodiwa pabusbar specification uye data rinoiswa pachiratidziro. Zviri nyore kushandisa uye unogona kugadzira busbar arc inobatsira uye inotaridzika zvakanaka.

Zvakanakira

Muchina uyu unoshandiswa kugadzira machining echikamu chearc yemisoro yebhazi ine H≤3-15mm, w≤140mm uye L≥280mm.

Musoro webhawa uchagadzirwa kuti uve nechimiro chakasimba.

Maclamp anoshandisa tekinoroji yekuisa pakati otomatiki kuti adzvanye musoro wekudzvanya zviri nani panzvimbo yekubata simba.

Chinosimudzira chinoshandiswa pamusoro wekudzvanya kuti chisimbise kugadzikana kwechinhu chebasa, zvichiita kuti pamusoro pechinogadzirwa pave nemhedzisiro iri nani.

Chibatiso chezvishandiso chepasi rose cheBT40 chinoshandiswa pakutsiva banga zviri nyore, kuomarara kwakaringana uye kunyatsoita basa nemazvo.

Muchina uyu unoshandisa screws dzebhora dzakanyatsogadzirwa nemazvo uye maguides akatsetseka. Magwara makuru anorema akasarudzwa kuti ape simba riri nani pamuchina wese, aderedze kudedera uye ruzha, awedzere kunaka kwebasa uye ave nechokwadi chekuti rakarurama uye rinoshanda zvakanaka.

Uchishandisa zvikamu zvemhando dzemuno nedzepasi rose, muchina uyu unogara kwenguva refu uye unogona kuvimbisa mhando yepamusoro.

Purogiramu inoshandiswa mumuchina uyu isoftware ye otomatiki yekugadzira mifananidzo yakagadzirwa nekambani yedu, ichiita kuti otomatiki ishande mukugadzira mapurogiramu. Mushandi haafanire kunzwisisa makodhi akasiyana-siyana, uye haafanire kuziva mashandisirwo enzvimbo yemichina yechinyakare. Mushandi anongofanira kuisa maparameter akati wandei nekutarisa magraphics, uye michina inogadzira otomatiki makodhi emuchina. Zvinotora nguva pfupi pane kugadzira mapurogiramu nemaoko uye zvinobvisa mukana wekukanganisa kwekodhi kunokonzerwa nekugadzira mapurogiramu nemaoko.

Busbar yakagadzirwa mumuchina uyu ine chitarisiko chakanaka, haina poindi inoburitsa mvura, ichideredza saizi yekabati kuchengetedza nzvimbo uye ichideredza zvakanyanya kushandiswa kwemhangura.

Chinangwa chedu chinofanira kunge chiri chekusimbisa nekusimudzira mhando yepamusoro uye sevhisi yezvinhu zviripo, panguva imwe chete tichigadzira zvigadzirwa zvitsva nemhinduro kuti zvizadzise zvinodiwa nevatengi vedu. Mutengo wakaderera weCNC Automatic Copper High Effiency Busbar Processing Bending Punching Cutting Machine. Bus Arc Machining Center Chamfering Machine, Isu tiri vamwe vevagadziri vakuru ve100% muChina. Makambani makuru ekutengesa anotenga zvinhu kubva kwatiri, saka tichakupai mutengo unoshanda zvikuru une mhando yakafanana kana muchida.

Mutengo wakaderera weAutomatic Busbar Machine neCopper Busbar Machine, Kana chimwe chezvinhu izvi chikakufadzai, munofanira kutizivisa. Tichagutsikana kukupai mutengo kana mawana ruzivo rwakadzama rwenyu. Tine mainjiniya edu eR&D ane ruzivo rwekuzvibatsira kuti agutse chero zvinodiwa nemunhu, Tinotarisira kugamuchira mibvunzo yenyu munguva pfupi iri kutevera uye tinotarisira kuwana mukana wekushanda nemi mune ramangwana. Tinokugamuchirai kuti muone kambani yedu.

Kugadziriswa

| Chiyero (mm) | Kurema (kg) | Kukura kweTafura yeKushanda (mm) | Kunobva Mhepo (Mpa) | Simba Rese (kw) |

| 2500*2000 | 3300 | 350*900 | 0.5~0.9 | 11.5 |

Magadzirirwo ehunyanzvi

| Simba reMother (kw) | 7.5 | Simba reServo (kw) | 2*1.3 | Max Torpue (Nm) | 62 |

| Muenzaniso weChibatiso cheZvishandiso | BT40 | Dhayamita yeChishandiso (mm) | 100 | Kumhanya kweSpindle (RPM) | 1000 |

| Upamhi hwezvinhu (mm) | 30~140 | Kureba Kwechinhu Chidiki (mm) | 110 | Ukobvu hwezvinhu (mm) | 3~15 |

| X-Axis Stoke (mm) | 250 | Stoke yeY-Axis (mm) | 350 | Kumhanya Kwekukurumidza Kwenzvimbo (mm/min) | 1500 |

| Kukwira kweBhorasikuruu (mm) | 10 | Kururama kweChinzvimbo (mm) | 0.03 | Kumhanya Kwekudya (mm/min) | 1200 |