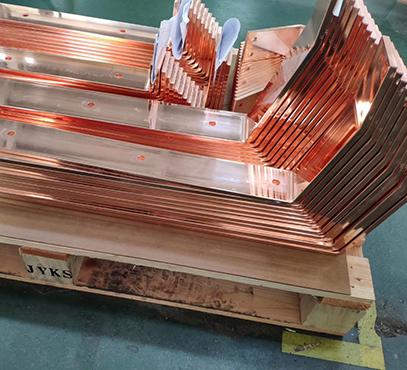

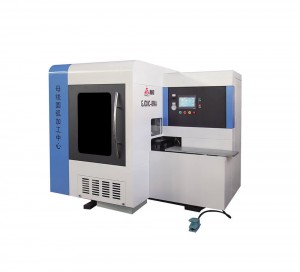

Kutengesa Kunopisa Muchina weCopper CNC Automatic High Effiency Servo Busbar Processing Bending Punching Cutting Machine

Takazvipira kupa sevhisi yekutenga kamwe chete iri nyore, inochengetedza nguva uye inochengetedza mari yemutengi wekutengesa muchina weFactory Copper CNC Automatic High Effiency Servo Busbar Processing Bending Punching Cutting Machine, Maitiro edu ehunyanzvi anobatsira zvikuru kubvisa kutadza kwezvikamu uye anopa vatengi vedu mhando dzakasiyana-siyana, zvichitibvumira kudzora mutengo, kuronga kugona uye kuchengetedza nguva dzose.

Takazvipira kupa sevhisi yekutenga kamwe chete, iri nyore kuchengetedza nguva uye inochengetedza mari yevatengi.Muchina weHydraulic Busbar weChina nemuchina weCopper Busbar, Tave tichishanda kwemakore anopfuura gumi. Takazvipira kuzvigadzirwa zvemhando yepamusoro uye rutsigiro rwevatengi. Parizvino tine mapatenti makumi maviri nemanomwe ezvigadzirwa zvekushandisa uye dhizaini. Tinokukoka kuti ushanyire kambani yedu kuti uwane rwendo rwakasiyana uye gwara repamusoro rebhizinesi.

Ruzivo rweChigadzirwa

GJCNC-BB Series yakagadzirirwa kukotama busbar workpiece zvinobudirira uye nemazvo

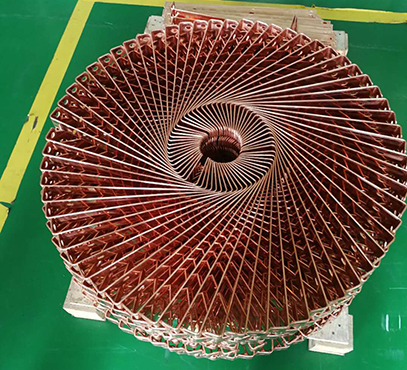

CNC Busbar Bender imuchina wekugadzirisa mabusbar bend unodzorwa nekombuta, Kuburikidza neX-axis neY-axis coordination, kudya nemaoko, muchina unogona kupedzisa mhando dzakasiyana dzezviito zvekukotama senge level bend, vertical bend kuburikidza nekusarudza madhiri akasiyana. Muchina unogona kuenderana nesoftware yeGJ3D, iyo inogona kuverenga nemazvo urefu hwekukotama. Software inogona kuwana otomatiki kukotama kwechikamu chebasa chinoda kukotama kakawanda uye otomatiki yeprogramming inoitika.

Hunhu Hukuru

Zvimiro zveGJCNC-BB-30-2.0

Muchina uyu unoshandisa chimiro chakasiyana chekukotama chemhando yakavharwa, une hunhu hwepamusoro hwekukotama kwemhando yakavharwa, uye zvakare une nyore kwekukotama kwemhando yakavhurika.

Chigadziko cheBend (Y-axis) chine basa rekugadzirisa angle error, kurongeka kwekukombama kwacho kunogona kusangana nekushanda kwakajairika. ±01°.

Kana iri muchimiro chekukotama chakamira, muchina une basa rekuzvibatanidza nekusunungura otomatiki, kushanda zvakanaka kwekugadzirisa kunovandudzwa zvikuru kana tichienzanisa nekusunga nekusunungura nemaoko.

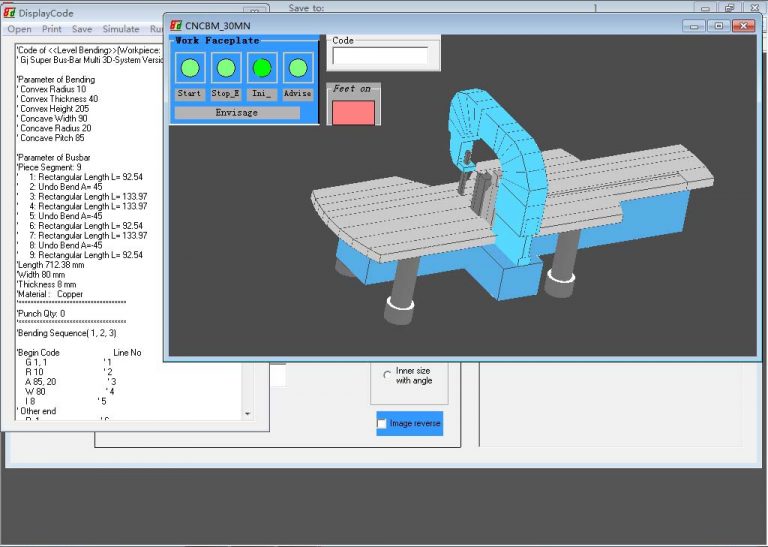

Software yeGJ3D Programming

Kuti tikwanise kugadzira auto coding, zviri nyore uye zviri nyore kushandisa, tinogadzira nekugadzira software yakakosha yeGJ3D. Iyi software inogona kuverenga yega zuva rega rega mukati mekugadzirisa busbar yese, kuitira kuti ikwanise kudzivirira marara ezvinhu anokonzerwa nekukanganisa kwekunyora makodhi nemaoko; uye sezvo kambani yekutanga yakashandisa tekinoroji ye3D muindasitiri yekugadzirisa busbar, software iyi inogona kuratidza maitiro ese ne3D model iyo yakajeka uye inobatsira kupfuura kare.

Kana uchida kugadzirisa ruzivo rwekugadzirisa michina kana ma parameter ekutanga e die. Unogona zvakare kuisa zuva neyuniti iyi.

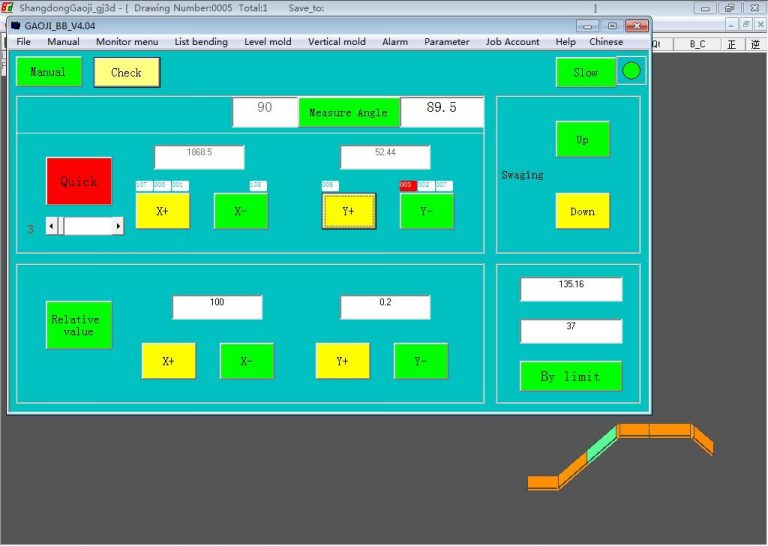

Sikirini Yekubata

Kushanda kwekombiyuta yevanhu kuri nyore uye kunogona kuratidza mamiriro ekushanda kwepurogiramu panguva chaiyo, skrini inogona kuratidza ruzivo rwealamu yemuchina; inogona kuseta maparamita ekutanga uye kudzora mashandiro emuchina.

Sisitimu Yekushanda Inomhanya Zvikuru

Kutumira sikuruu yebhora kwakarurama kwazvo, kwakabatana negwara rakarurama kwazvo, kunyatsoita zvinhu nemazvo, kunoshanda nekukurumidza, kushanda kwenguva refu uye pasina ruzha.

Chishandiso chebasa

Magadzirirwo ehunyanzvi

| Huremu Hwose (kg) | 2300 | Chiyero (mm) | 6000*3500*1600 |

| Kumanikidzwa Kwemvura Kukuru (Mpa) | 31.5 | Simba Guru (kw) | 6 |

| Simba Rekuburitsa (kn) | 350 | Stoke huru ye silinda inokotama (mm) | 250 |

| Saizi Yezvinhu Zvakanyanya (Kukotama Kwakatwasuka) | 200*12 mm | Saizi Yezvinhu Zvakanyanya (Kukotama Kwakatsetseka) | 120*12 mm |

| Kumhanya kwakanyanya kwemusoro unokotama (m/min) | 5 (Modhi inokurumidza)/1.25 (Modhi inononoka) | Angle Yakakotama (dhigirii) | 90 |

| Kumhanya kwakanyanya kwechinhu chinovhara divi (m/min) | 15 | Stoke yechinhu chinovhara divi (X Axis) | 2000 |

| Kukombama Kwakaringana (dhigirii) | Muripo wemotokari <±0.5Muripo wemaoko <±0.2 | Kupamhama kweU-shape (mm) | 40 (Cherechedza: ndapota bvunza kambani yedu kana uchida mhando diki) |